At Friedrichshafen Ham Radio flea-market 2022, I bought an old tired Marconi Instruments Radio Communications Test Set 2955 which I have spent a bit of time restoring. I now have it passing all of it self test, and the functionality seems good.

During the time I spent digging through the service manuals (link here) for the unit and my time exploring the Marconi Instruments GroupsIO, I noticed there was an updated firmware for the unit. Mine shipped with the very earliest V10 firmware. I saw ROM files in the forum Files section for V16. There are some upgrades from V10 to V16, though, rumour has it that anything above V13 isn’t much of an upgrade unless you’re using some of the cellular testing accessories. The V16 firmware files can be found here inside the Marconi Instruments GroupsIO Files section (along with many other useful things). Definitely a very useful group with knowledgeable people inside!

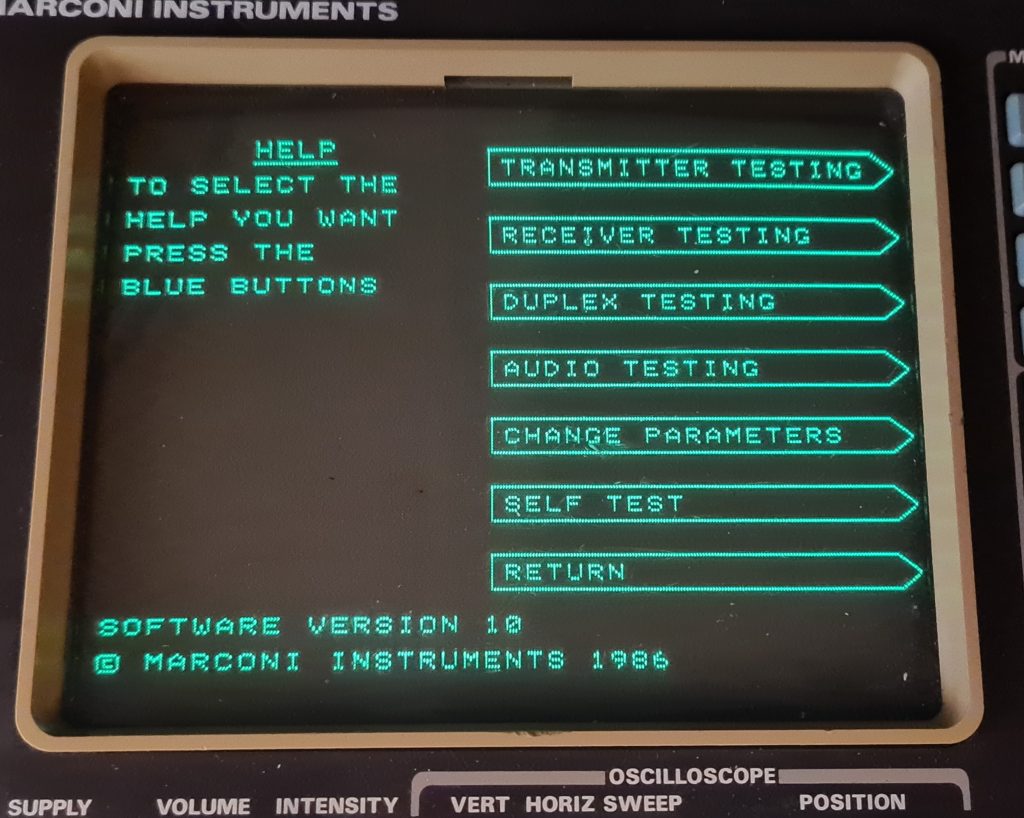

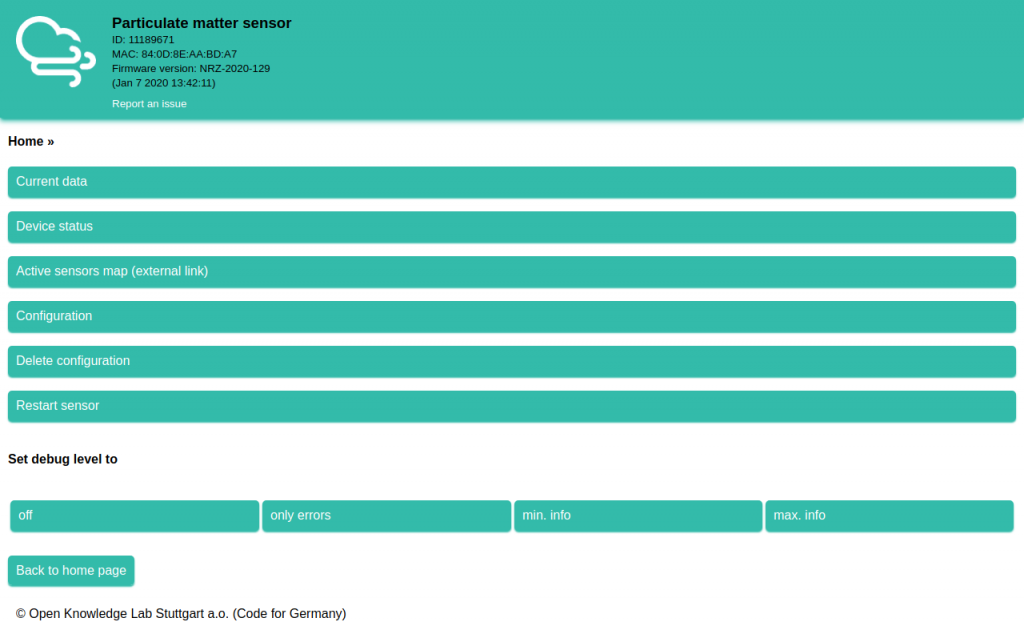

Below, we see the original version 10 firmware, dated 1986.

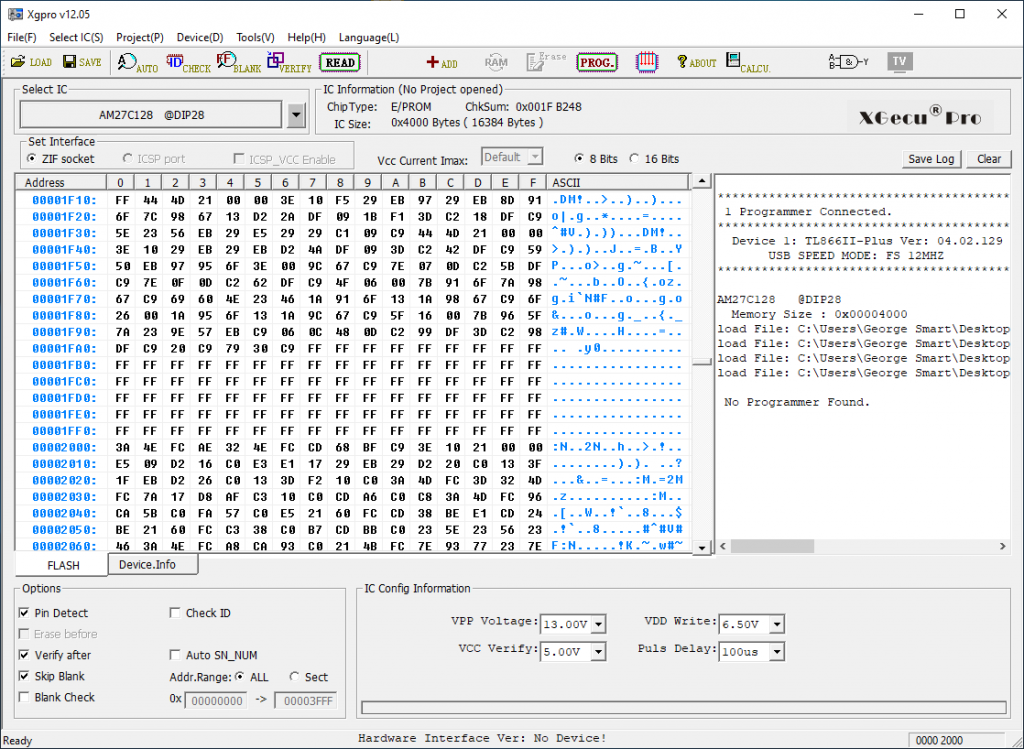

The EPROMs which need upgrading are IC9, IC10, IC11 & IC12 on the processor board. These are three of 27C128 128kbit (16kByte) EPROMs [IC9-IC11] and one of 27C64 64kbit (8kByte) EPROM [IC12]. I replaced all mine with the larger 128kbit 27C128 parts, copying the 27C64 binary image into both the lower (offset 0x0000) and upper (offset 0x2000) halves of the EPROM, so irrespective of the state of pin A13, the data output would be the same.

Rather than UV erase the original EPROMs in the machine, I purchased additional ones online (I got mine from AliExpress, but eBay, etc., all sell them). Mine ended up being brand new, never used, but previous ones I’ve bought were pulled from old equipment and needed erasing beforehand.

Using an EPROM programmer, I programmed the four 16kB ROMs onto the blank chips. This took around 10 seconds each using my TL866ii+ programmer.

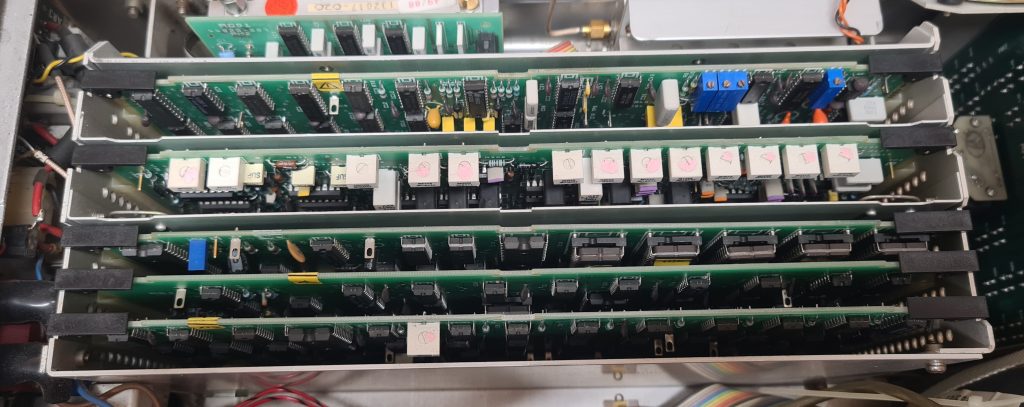

To change the EPROMs in the Marconi 2955, you need to remove the top cover to be greeted with the insides of the 2955. The CPU board (AB4) we need is inside the locked metal cover. These are rotate-clips, not screws, so go easy on them!

Once you’re inside the metal screening box, you’ll see some boards stacked into the main motherboard along the bottom. We need CPU board AB4, which is the 3rd board up from the bottom of the picture (closest the screen). Use the ‘ears’ on the side to help lever the board from the motherboard socket below and slide the board out.

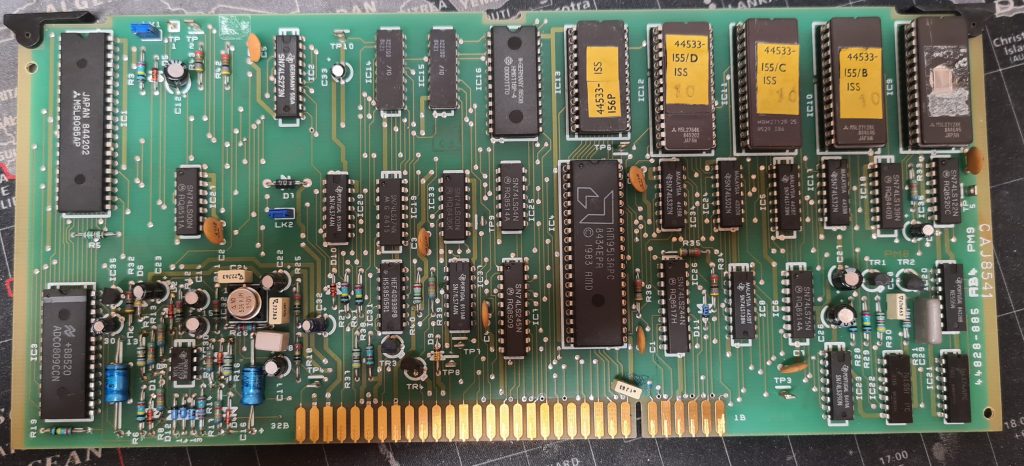

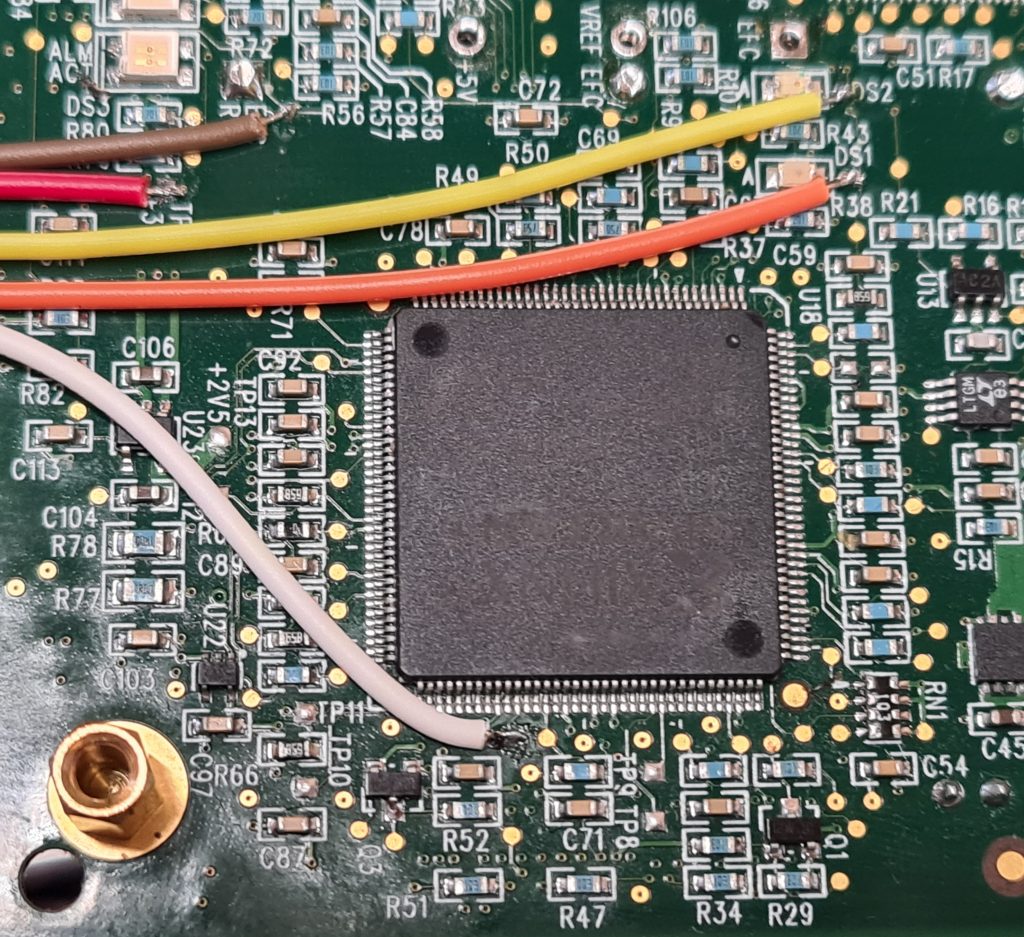

The CPU board AB4 is shown below. You can see the manufacturer stickers on 3 of the 4 larger EPROMs and the smaller flash EEPROM. From left to right, the 4 stickered devices are IC13, IC12, IC11, IC10 and the final, rightmost is IC9 with missing sticker (it had fallen off inside the machine).

IC13 is a flash chip (Xicor X2816AP) with your unit’s calibration data stored within – don’t overwrite this one any online! You can of course read/back up your calibration data if needed. I decided to copy my flash EEPROM IC13 into a new part, so that I could keep all of my older V10 PROMS together. I was worried that if something went wrong and the V16 firmware had ‘updated’ the formatting of the data in IC13, I may not be able to go back. I used a CSI CAT28C16AP that I had in the shack as I wasn’t originally intending to touch IC13. If you decide to replace IC13 also, I would suggest getting the exact part used in case it matters. These early flash chips are a bit fussy with timings, etc., and so interoperability isn’t guaranteed. That said, mine has been fine.

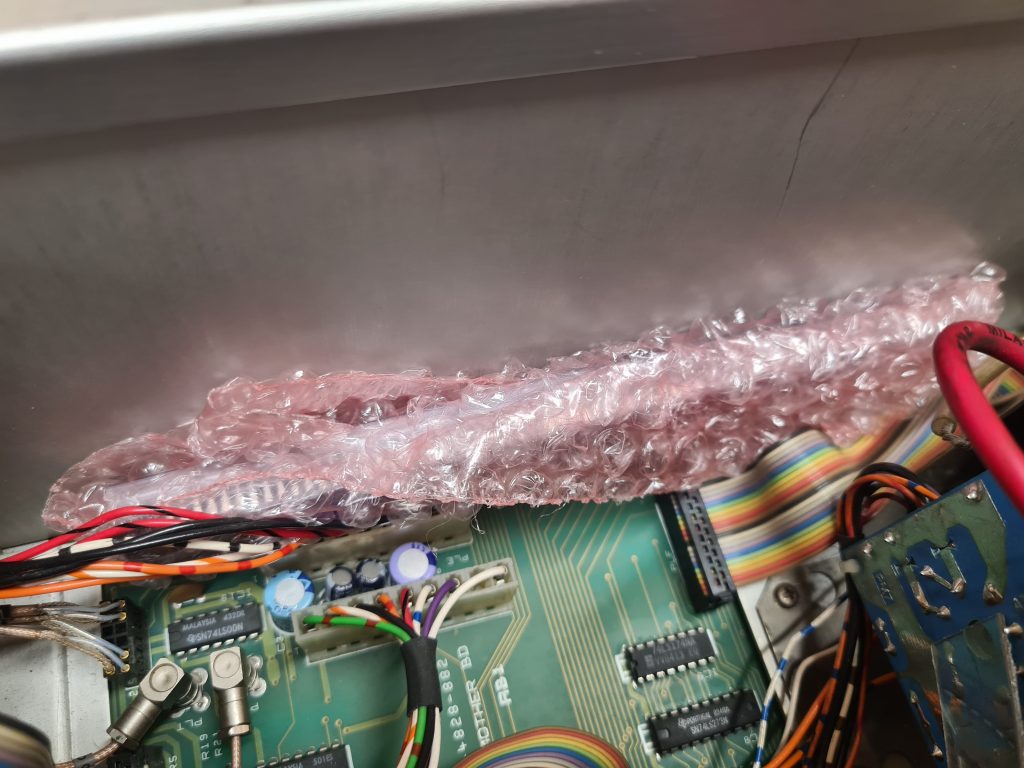

The 5 devices were replaced. I used a label printer to sticker each ROM as I wrote and verified its contents. The original chips were placed inside an antistatic IC tube, and wrapped in ESD-safe bubble-wrap , which I tucked inside the machine between the screened box and the power supply cabling on the motherboard. They sit nicely there, can’t move, and will be available should anyone wish to revert the machine.

After reassembling the unit, I fired the test-set up, and to my relief it booted straight up!

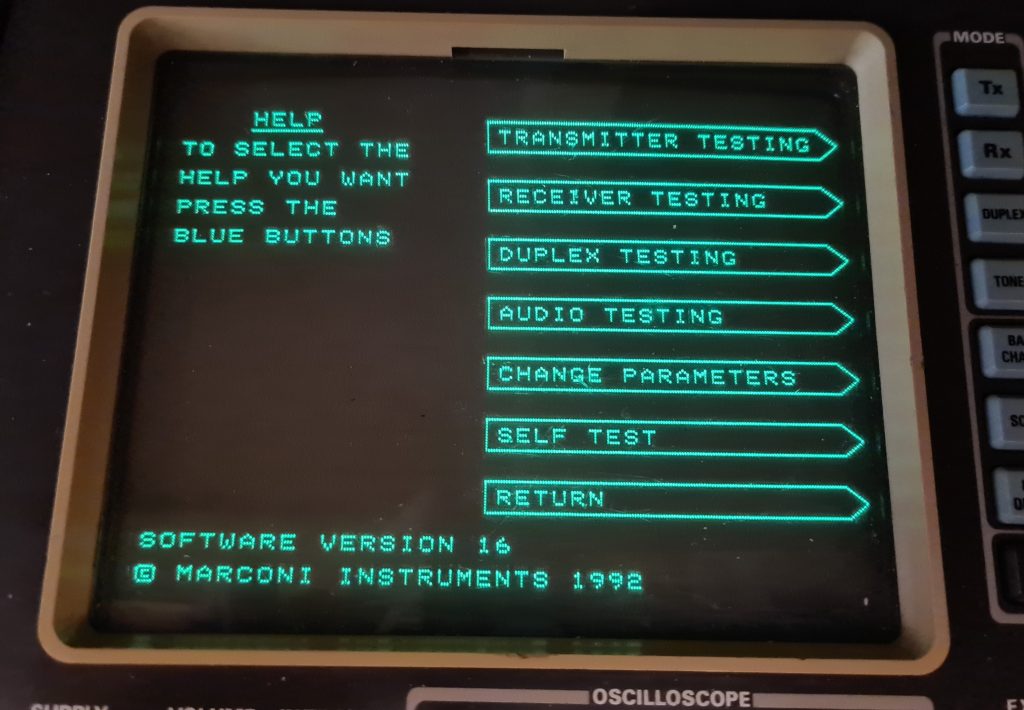

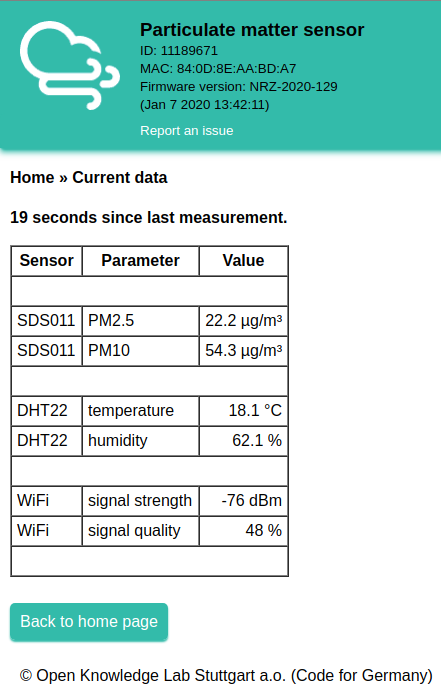

I was able to confirm the firmware upgrade had worked – below we see the software version is now version 16 (dated 1992).

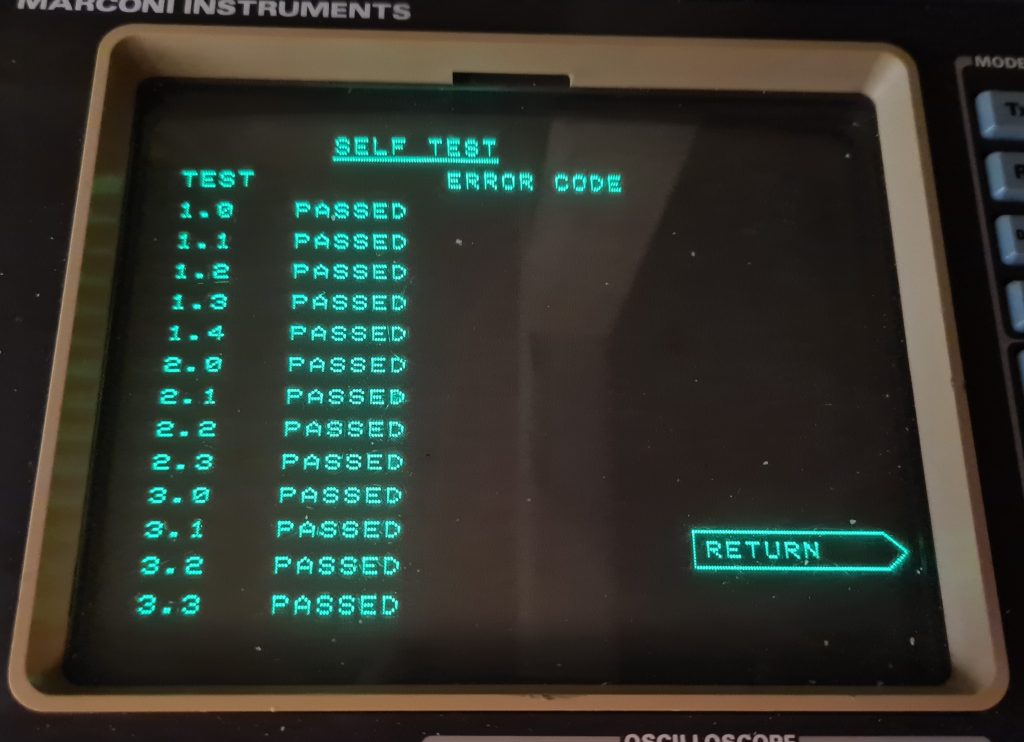

Pressing the self-test button confirmed the basically functional. Excellent!